Powder coating

Minka has been an expert in powder coating for almost 50 years. Thanks to our many years of experience, we are a reliable partner for the surface finishing of a wide variety of products.

Powder Coating

Powder coating is a process that is primarily used to refine the surface of metals. At our location in St. Lorenzen in the Mürztal, we coat, for example, gates, fences, window and door frames, window sills, railings, grilles, pipes, sheets, structures and various small parts. Powder coating is also suitable for many other products made of aluminum, cast aluminum, bright steel, galvanized steel and stainless steel (NiRoSta). Thanks to our almost 50 years of experience in the field of powder coating, over a hundred business customers already trust in Minka. To date, we have particularly supported companies in the metal, steel, fence, door, window, facade and winter garden construction sectors, as well as metalworking companies and glaziers.

How does powder coating work?

Powder coating basically consists of three consecutive work steps, most of which are automated at Minka:

1. Pre-treat

In order to optimally prepare the material for powder coating, a so-called pretreatment first takes place. Using certain chemical and mechanical processes, the workpiece is freed from any dirt. In addition to cleaning, pretreatment is also necessary to increase the material’s corrosion protection. This ensures a long service life for the coated parts and the paint sticks better.

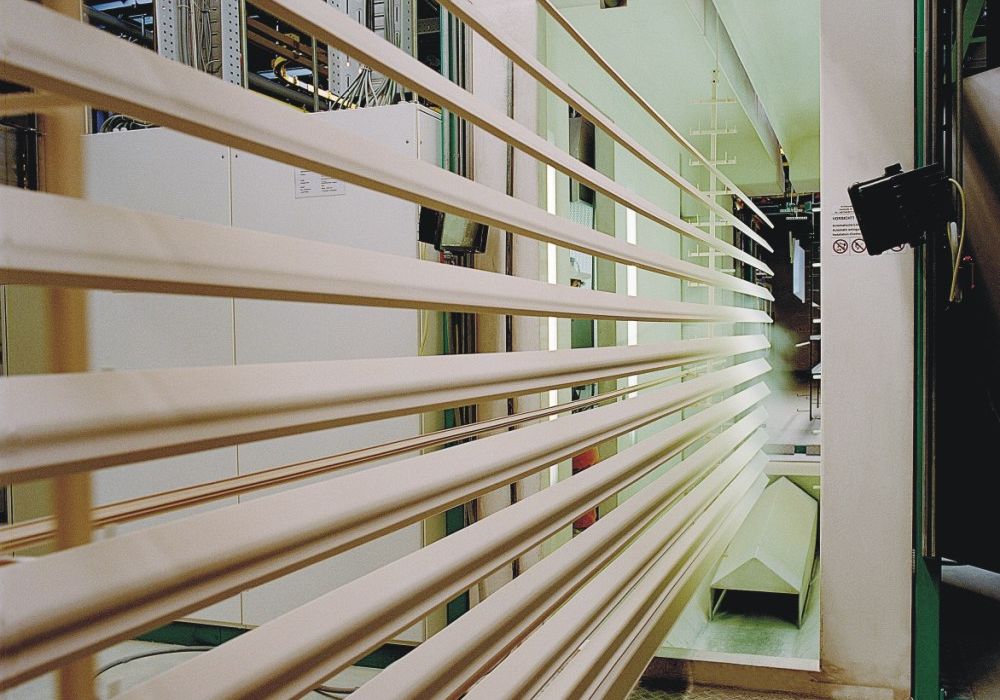

2. Applying the lacquer powder

After pretreatment, the actual powder coating process begins. The paint powder is applied to the surface of the workpiece using special powder spray guns. The paint particles in the powder cloud are electrically charged and settle on the material. This creates an even layer of paint on the surface.

3. Burning and drying

After applying the powder, the workpiece is placed in a so-called curing oven. There the material is heated to temperatures between 120 and 240 degrees for up to 30 minutes. This creates a resistant, long-lasting lacquer layer. In technical language, this last step is also known as networking.

How does powder coating work?

Powder coating basically consists of three consecutive work steps, most of which are automated at Minka:

- Wide range of colors and wood decor coating

- Different levels of gloss (matt to glossy) and surface structures (fine to coarse structure)

- High resistance and excellent corrosion protection

- Efficient and high quality processing

- Resource-saving and environmentally friendly process

- Own, free and fast fleet

Thanks to our many years of experience, our flexible production and our high customer orientation, we are a reliable all-round partner in the field of powder coating. For those who need things to happen particularly quickly, we also offer express coatings!

Interest?

Are you interested in Minka powder coating or do you have further questions on this topic? Our coating team is at your disposal and looks forward to your inquiry: